Ryder Propack Pvt Ltd

Supplying seamless, PBL and ABL tubes for cosmetic,

oral care and pharma sector.

Have a question? Get in touch!

+91-9818403717+91-9718168740

At Ryder Propack, we specialize in manufacturing a variety of tube packagings for cosmetic, pharmaceutical and oral care sector. Our expertise lies in producing an extensive range of Seamless, Plastic Barrier Laminate (PBL) tubes and Aluminum Barrier Laminate (ABL) designed to cater to the diverse needs of our clients.

Our product line covers tubes with capacities ranging from 5 ml to 300 ml, ensuring versatility and adaptability for various applications. Each tube we produce stands as a testament to our commitment to quality, functionality, and aesthetic appeal, making them ideal for a variety of products in the pharma and cosmetic sectors.

We, Ryder Propack Pvt. Ltd. are well known for our excellent manufacture and supply of tube packaging products for Pharma and Personal Care industry in the market. Our range of multi layered laminated tubes are appreciated by the experts of pharmaceutical, FMCG, oral, cosmetics and many other industries. In the domains, our capability to produce both PBL (Plastic Barrier) as well as ABL (Aluminum Barrier) tubing solutions is greatly applauded. We offer various dias (from 16mm dia to 60mm dia tubes) for Pharma, oral care and personal care sectors. They come with a guarantee of robustness, quality and dimensional perfection.

Our quality and timely delivery are well established in the market place with the growing satisfied and elated customer list. Our factory is located at Gurugram (Haryana, India), which is strategically built at a premier industrial area and is not far from the pharma hub of Haridwar, Poanta Sahib, Baddi, etc. Further, we have a top notch warehousing facility where all of our manufactured tubes and procured raw materials are stored.

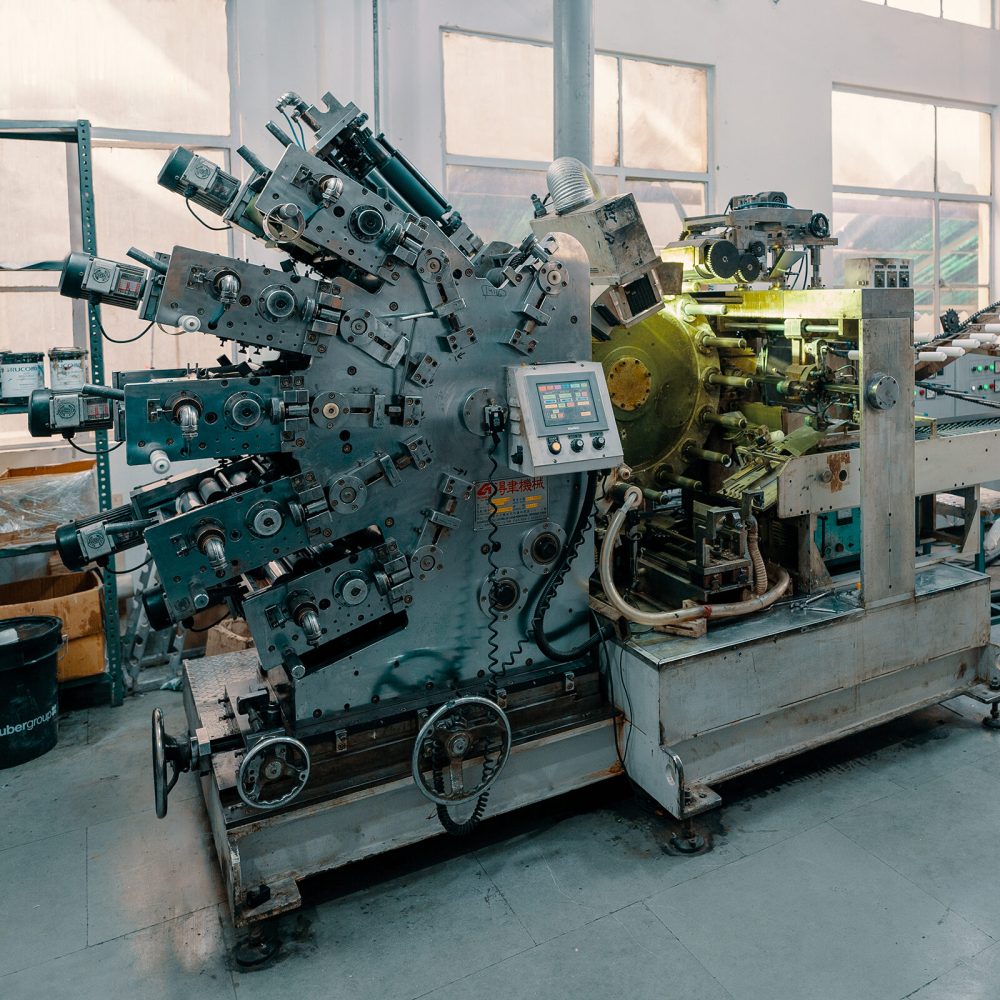

Printing options

At Ryderpro Pack, our seamless tubes are brought to life with a state-of-the-art six-color offset printing machine, offering exceptional quality and precision. We also provide versatile labeling and screen printing options to cater to diverse design requirements. For our ABL and PBL tubes, we utilize high-quality eight-color flexo printing, enhanced with sophisticated foil options. Our printing techniques are versatile, ranging from matte and gloss lacquer finishes to half-tone and solid color printing, culminating in exquisite hot foil stamping. Each process is meticulously crafted to ensure your packaging stands out with unparalleled vibrancy and sophistication.

Production Process

- Grammage Test

- Drop Test

- Leakage Test

- Air Leakage Test

- MFI Test

- Printing Color Test

- Foil Tape Test

- Label gumming test

- Cap Up- Down Counting Test